Pitch Perfect Tooling

Our tool room offers a comprehensive suite of tooling services, ranging from routine maintenance and refurbishment right through to design and manufacture. Substantial investment in new technology and machinery means that we are able to take on the most complex of projects.

RUTLAND PLASTICS AND REGA

PITCH PERFECT TOOLING

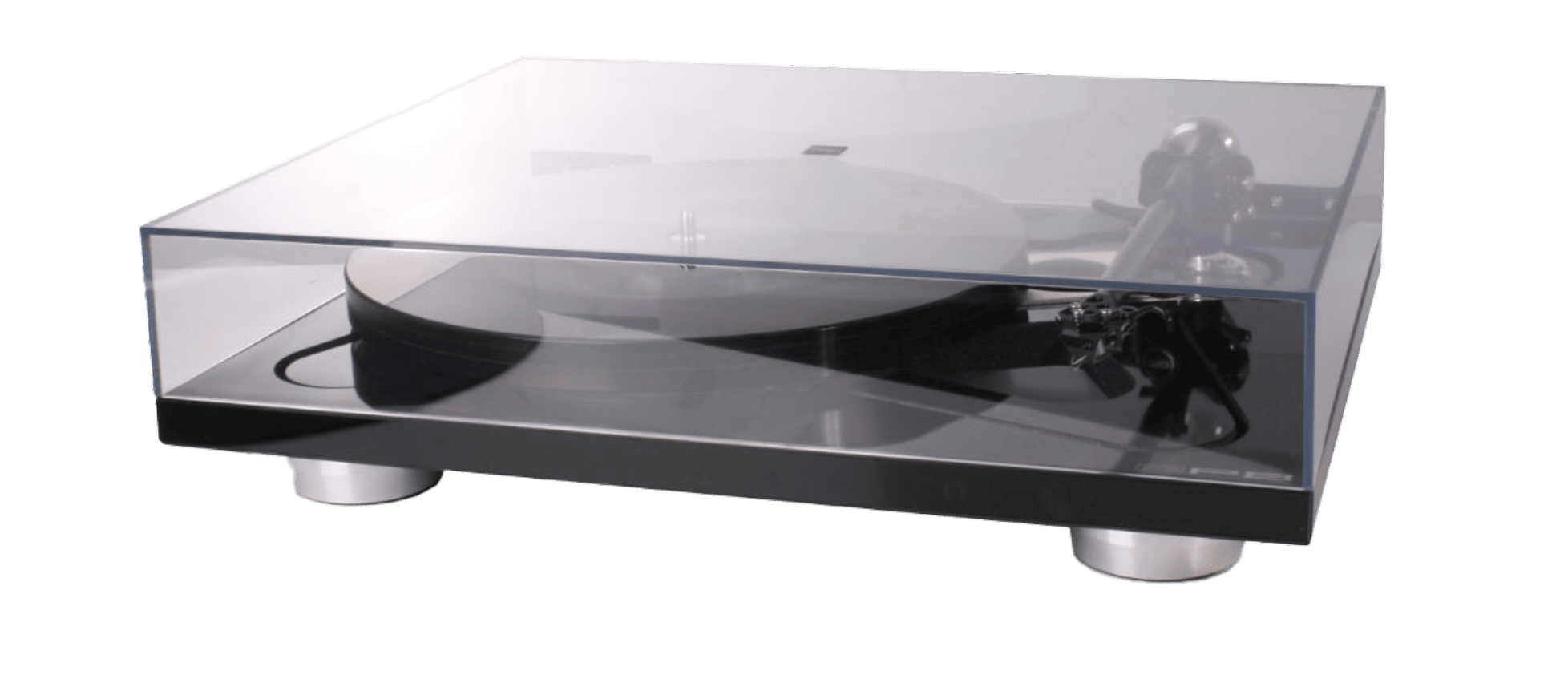

We were therefore ideally placed to assist quality audio equipment specialists Rega. When the company decided to move production of their clear acrylic turntable dust covers back to the UK, they specifically sought a manufacturer with combined expertise in both plastic injection moulding and tool making, who would be able to meet their exacting standards. Rega’s products are world class and are known for their minimalistic design. Not just an aesthetic choice, but a serious technically based decision. Rega state “Mass absorbs energy and lost energy equals lost music”.

Victims of their own success in a way, Rega had originally produced their minimalistic dust covers by hand. However, as orders significantly increased and production was placed with a Danish moulder, problems developed. It became necessary to mould tinted acrylic to hide blemishes and after three different mould tools Rega took the decision to re-shore production.

On their own admission, the dust cover breaks every basic design rule for injection moulding. It has no draft angles, which is a major issue for de-moulding, and features sharp corners and edges. Not to mention the requirement for a clear material with a faultless mirror-like sheen. Obviously, there is no tolerance for imperfection.

Tackling all the concerns head on, we initially struggled with moulding from the existing tool. Not only because of the design constraints but additionally we discovered two vital processes in the making of the tool had not been addressed. These omissions were contributing factors for the failure to achieve the clarity required. We also discovered that the quality of the tool steel that had been used was unsuitable for this type of moulding. Using our combined skills across our departments, we proposed a material which would match the quality and appearance Rega desired and would additionally deliver cost savings. Our 3D printer enabled us to build test samples which allowed us to show Rega our re-design vision in a clear tangible format. This greatly assisted them in visualising our suggestions and agreeing to our recommendations.