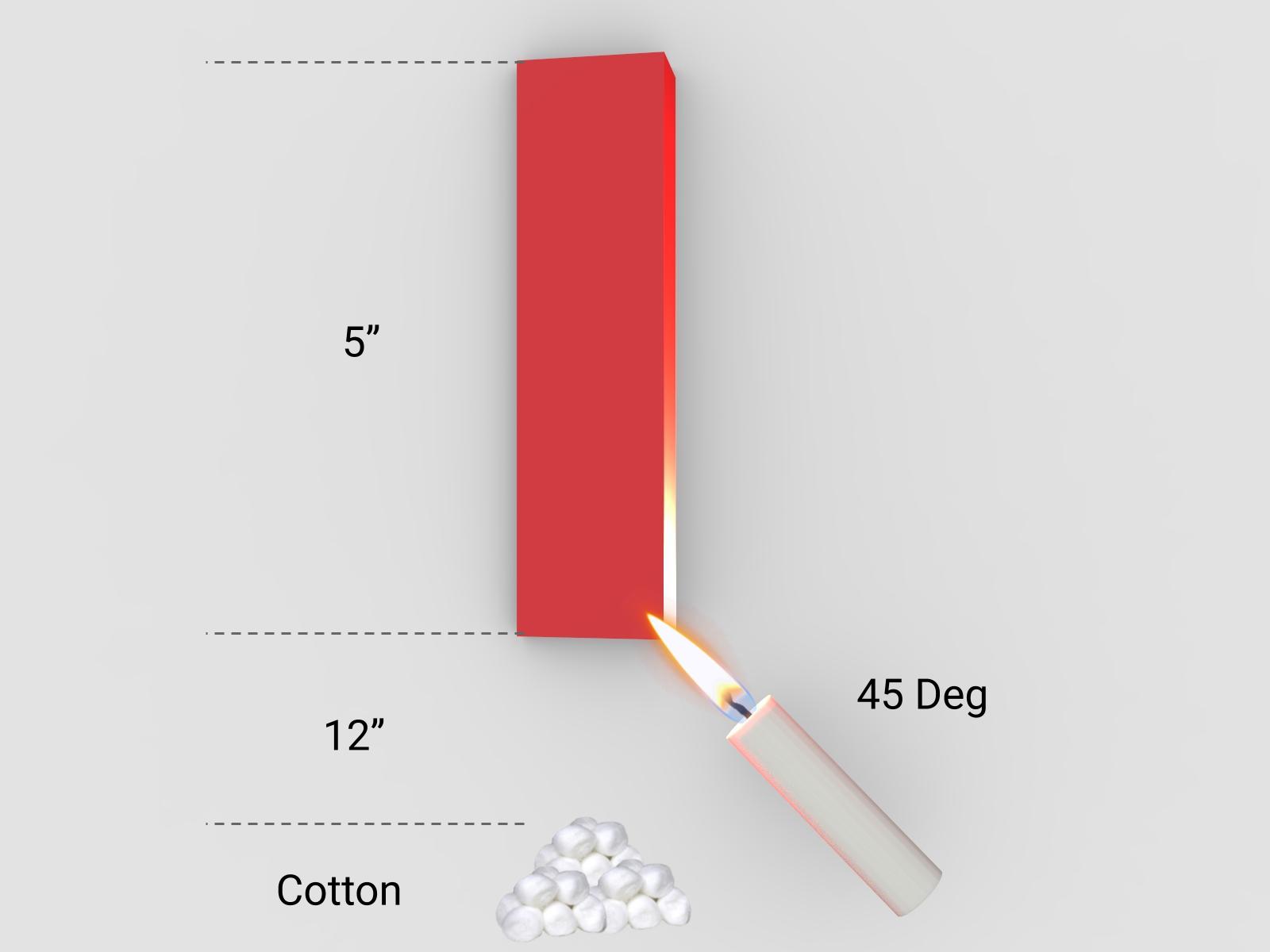

FLAME RETARDANCY

In certain applications a degree of flame retardancy may be required.

Polymers provide various levels from virtually non-existent (HB) through to extremely good (5V), with a wide range in between. When looking for a flame retardant polymer the most common requirement is V0.

MATERIAL CONSIDERATIONS

Some plastics are inherently more suited to applications requiring flame retardancy than others. For example, although it is possible to obtain a FR grade of polypropylene it requires a heavy loading of the necessary additive to achieve it which can substantially alter the properties of the base material. On the other hand, there is a wide choice of FR grades of ABS and PC/ABS. There are other materials that are inherently flame retardant such as Sulphones, PPO and PPS.

DESIGN

How does design impact on flame retardancy? Well, when looking at the FR ratings on a datasheet it is important to check the thickness of the test specimen. For example, there is a grade of ABS we use that is V2 at 0.8mm thickness but V0 at 1.5mm. Therefore, it may be possible for you to achieve the required level of flame retardancy just by increasing the thickness of the part. Although this may increase the weight and manufacturing cost of the part it could well be a cheaper option than using a more highly rated, and therefore more expensive, polymer.

FURTHER READING OR LINKS TO ALL GUIDES?

- Design Guide

- Design Development

- Design For Appearance

- Design For Assembly 1

- Design For Assembly 2

- Design For Assembly 3

- Design For Cost Consideration

- Design For Economy

- Design For Mouldability 1

- Design For Mouldability 2

- Design For Mouldability 3

- Design For Precision

- Design For Recyclability

- Design For Stiffness

- Design For Strength

- Design For Time

- Design Summary

- Flame Retardancy

- Flexibility

Free design guide

"*" indicates required fields