DIP MOULDING

Please Note: This page is for information purposes only. Rutland Plastics is an Injection Moulder and does not offer dip moulding services.

PROCESS

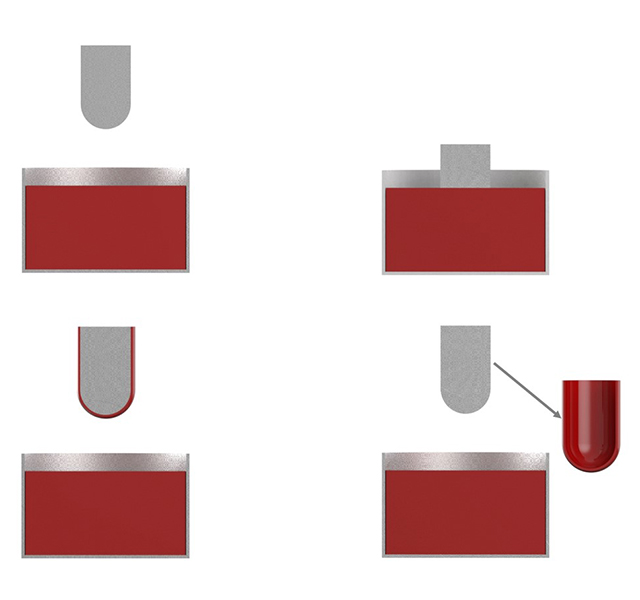

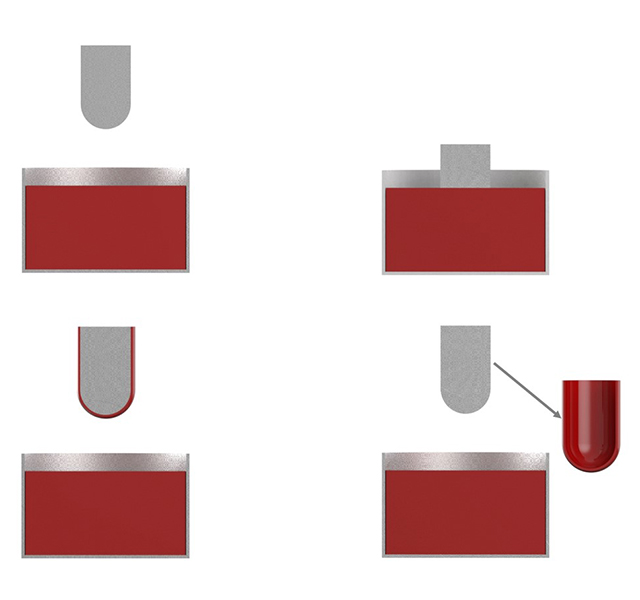

Dip moulding is a manufacturing process similar to candle making in its methods. Heated metal moulds are dipped in a tank of liquid material. This material may be heated or at ambient temperature. The moulds are extracted and then put through a baking process to cure the material before the part is then stripped from the mould. Once baked the material does not return to the liquid state.

As with candle making, the mould may be dipped several times to build up layers. The mould may also be dipped into different materials to create different effects. For example, handles for hand tools may be dipped first in a hard material to provide a tight fit and durability, and then into a softer material for a comfortable grip.

MATERIALS

The materials used are known as Plastisol and are vinyl based. There is now a wide range of these materials offering variations of hardness, colours, matt or gloss finish as well as foams and grades that look and feel like suede or rubber.

APPLICATIONS

- Handles for hand tools

- Caps

- Plugs

- Surgical gloves

- Covers

ADVANTAGES

- Low tooling costs

- Short lead times

- Ability to vary surface texture without the need for new tooling

- Ability to mould complex hollow shapes

DISADVANTAGES

- Unable to withstand high temperatures

- Large parts are difficult to dip mould

- Difficult to control the dimensions of outer surfaces