RUTLAND PLASTICS WORK WITH SOME AMAZING PEOPLE

CASE STUDIES

RUTLAND PLASTICS AND ITG

BRITISH MANUFACTURING

ITG (Induction Technology Group) are manufacturers of high performance air filters for motorsport and road car applications. Applying unique manufacturing techniques, strict quality systems, best design methodology and hand built process provides exceptional standards of manufacture and fit for their products.

ITG approached Rutland Plastics to investigate whether we could improve on the manufacturing process of one of their filter end caps. The cap was previously vacuum formed but ITG wanted to add texture and engraving to the product at the point of manufacture to eliminate the need for double handling, therefore reducing cost and also improving the aesthetic of the product. Injection moulding was the obvious choice of manufacturing process to achieve all their objectives.

Simon Grainger, Rutland Plastics’ Technical manager, said ‘ Richard from ITG approached us to help develop the air filter end cap, with a brief to use the best techniques to achieve the desired technical performance whilst maintaining the aesthetic of ITG air filters. The material selection in this project was key as the cap had to be able to be bonded with other components, withstand under-bonnet conditions and also have a high gloss level to achieve the desired engraving effect. ABS was selected as the best material to achieve this. We worked closely with our toolmakers and were so confident in the end result that we textured, polished, sampled and got final approval for the product after the first off T1 trial.’

Richard Clews of ITG said ‘We are proud to be a British business and we love working with other British manufacturers. Rutland Plastics have provided support and expertise throughout the whole design and manufacturing process and it’s great to work with a team who share the same values as us. Our attention to detail, our quality systems and knowledge of best design methods together with our unique manufacturing techniques, ensure that ITG customers have the best product. Working in partnership with Rutland Plastics ensures this continues.’

Rutland Plastics has worked closely with ITG for some time now and provides various mouldings of different sizes using machines ranging from 80 tonnes to 650 tonnes. We have started using recycled PP talc filled material in some of the other products we manufacture for ITG and we are always looking for ways to improve the manufacturing process for our customers.

RUTLAND PLASTICS AND REGA

PITCH PERFECT TOOLING

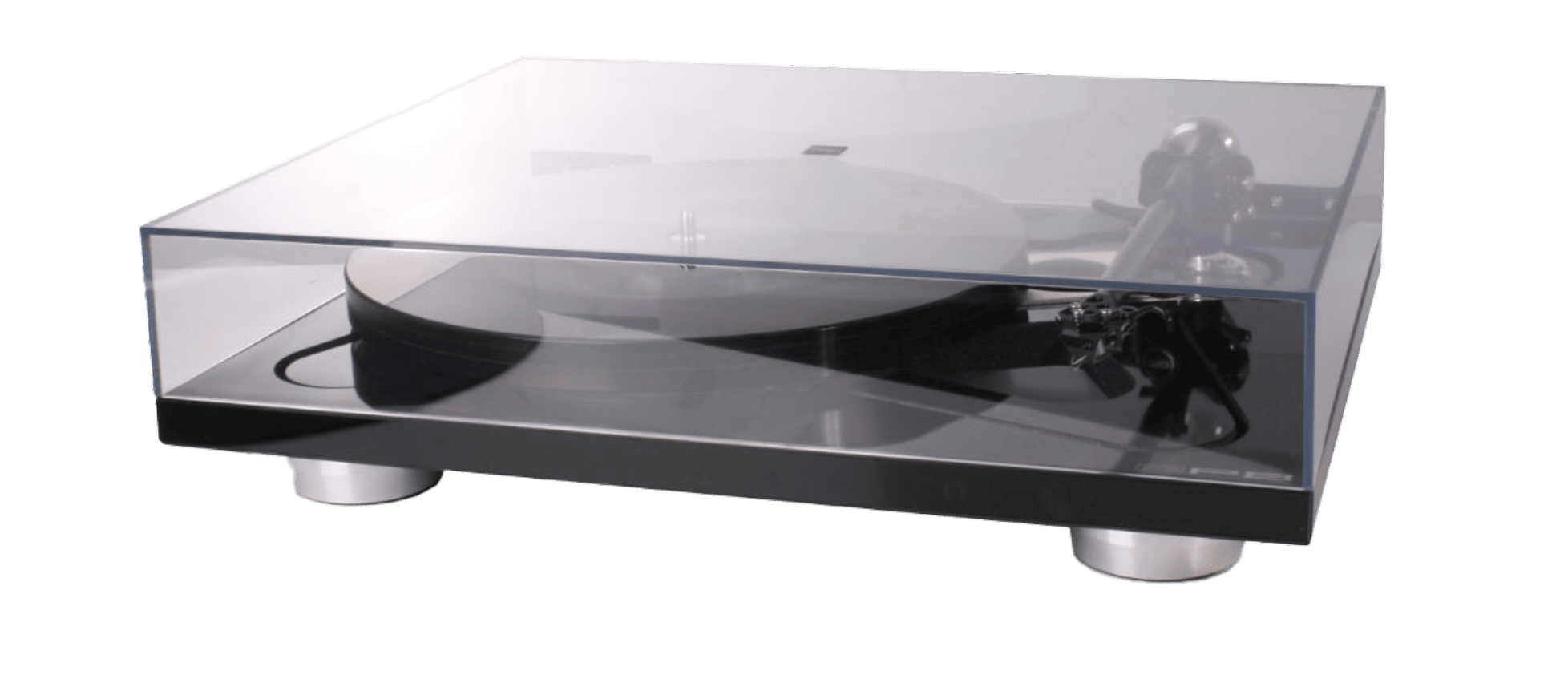

We were therefore ideally placed to assist quality audio equipment specialists Rega. When the company decided to move production of their clear acrylic turntable dust covers back to the UK, they specifically sought a manufacturer with combined expertise in both plastic injection moulding and tool making, who would be able to meet their exacting standards. Rega’s products are world class and are known for their minimalistic design. Not just an aesthetic choice, but a serious technically based decision. Rega state “Mass absorbs energy and lost energy equals lost music”.

Victims of their own success in a way, Rega had originally produced their minimalistic dust covers by hand. However, as orders significantly increased and production was placed with a Danish moulder, problems developed. It became necessary to mould tinted acrylic to hide blemishes and after three different mould tools Rega took the decision to re-shore production.

On their own admission, the dust cover breaks every basic design rule for injection moulding. It has no draft angles, which is a major issue for de-moulding, and features sharp corners and edges. Not to mention the requirement for a clear material with a faultless mirror-like sheen. Obviously, there is no tolerance for imperfection.

Tackling all the concerns head on, we initially struggled with moulding from the existing tool. Not only because of the design constraints but additionally we discovered two vital processes in the making of the tool had not been addressed. These omissions were contributing factors for the failure to achieve the clarity required. We also discovered that the quality of the tool steel that had been used was unsuitable for this type of moulding. Using our combined skills across our departments, we proposed a material which would match the quality and appearance Rega desired and would additionally deliver cost savings. Our 3D printer enabled us to build test samples which allowed us to show Rega our re-design vision in a clear tangible format. This greatly assisted them in visualising our suggestions and agreeing to our recommendations.

RUTLAND PLASTICS AND ITG

GETTING OUR TEETH INTO

A NEW PRODUCT

A proposal for a travel case to protect a battery toothbrush from turning on mid-journey and draining its power was presented to us as a conceptual design. “The brief was simple to begin with – a box for my electric toothbrush”, explains Ged McCall, Schelle founder. The vision was for a product that would be lightweight and compact, but also robust.

Our design team discussed the manufacturability of the new product case with the customer and suggested improvements to both the outer and inner features. These enhancements meant that the cost of the mould would be reduced and additional savings could be made on assembly costs. We were also able to recommend the use of a polypropylene material with antimicrobial additives. We trialled the design in a number of different grades, finding the optimum solution.

The result has been a dishwasher safe, shatterproof case, moulded in eight colours. Working with Rutland Plastics saves time, money and results in a suitable plastic moulding and tool design from the outset. All through the process we share our expertise with customers and together we optimise the choice of plastic material, physical shape, ease of production, cost and performance. To achieve the most cost-effective and sustainable solution for production it’s always optimal to design parts in their finished form, i.e. without the requirement for secondary operations and with no waste of materials

RUTLAND PLASTICS AND VIRIDIAN SYSTEMS

REPLACING METAL WITH PLASTICS

Material challenges are always interesting and when Viridian Systems approached us to replace a metal component with a plastic injection moulded alternative there were many considerations. Viridian provides environmental solutions for the landfill industry. They are renowned for their range of automatic self-regulating VP pumps which assist in the management of landfill leachate. The company was keen to reduce the part weight, but at the same time, it had to be considered that the pumps are manufactured to tight tolerances, high specifications and technical accuracy. Is it possible to replace metal with plastics?

The Rutland Plastics Design Team recognised that the plastic material would need to be very strong as the pumps are continually under immense stress. Additionally, it would need to be able to withstand high temperatures and because of chemicals encountered in the leachate, be corrosion resistant. After selecting the most suitable material, it became clear that an exact copy of the original metal design would not offer the strength required. Our team worked on a series of modifications to gain greater strength and the final result totally fulfilled the customers’ requirements. Furthermore, the success of this part prompted Viridian to explore the replacement of a further component from the same product. We were able to design a plastic replacement for the float used in the pump, the manufacture of which had previously produced a large amount of scrap. Rutland Plastics created a highly unusual solution for the material to facilitate the perfect density for the part to function efficiently. We were delighted when Viridian reported that the new plastic parts were more than a match on performance and additionally outperformed the originals quite significantly on cost. This result proves that replacement of metals with plastics can be highly successful.