Flymount

With an increasing trend for people to use helmet mounted cameras to record themselves when cycling, skiing, skateboarding or during some other sporting activity, why not use smartphones instead? Joe Knapton of Flymount, specialists in the field of sporting camera mounts, had an idea for a helmet mounted iPhone case. All he needed was someone to bring his ideas to fruition – Rutland Plastics.

Flymount was founded in 2006 by Joe Knapton and his wife, Imogen. Joe, a keen windsurfer, spent his early years abroad pursuing his sport of windsurfing. There were ups and downs along the way and following an enforced end to a trip to Morocco, he met his wife. They set up home in southern Spain and it was from here they started Flymount.

The idea was simple enough, a fixing kit to enable a camera to be attached to a windsurf rig to take action pictures. The first mounts were made from things available in the local hardware store. The concept was to produce a fixing for an early waterproof Pentax compact camera to get some footage and a heavy metal mount was unsuitable for the end of a mast. The aim was to have a product allowing a compact camera to be attached to a windsurf rig or other action sports equipment, without affecting performance.

The company still make the world’s only dedicated point of view (POV) mount for any camera, including GoPro, having been continually evolved and refined to become the best action camera mount on the market.

With the increasing sophistication and camera quality of smartphones, the next obvious step was to eliminate the need for a conventional or GoPro camera altogether in certain situations.

There are a number of different helmet mounts for compact cameras or GoPro. These obviously require the purchase of a camera, if you do not already have one. The nature of the mount also meant that the result was rather unwieldy once mounted and no protection was offered to the camera in the event of the helmet being dropped or knocked. Similarly, there are also some iPhone helmet mounts available but they only allow the phone to be mounted in a forward facing position. This not only looks wrong but offers no protection to the phone which is highly vulnerable in the way it is mounted.

Flymount developed a patent pending optical technology which enabled the use of an iPhone to record footage whilst flush against a helmet rather than with the camera facing outwards. What was then needed was a low-profile case to not only protect the iPhone but also to fit easily to solid and vented helmets.

Rutland Plastics was already a supplier to Flymount. When the company wanted to bring their mould tools for the Camera Mount back from China to the UK, Rutland Plastics offered the support they were looking for. Carrying out remedial work on the tools and supplying fully assembled parts to Flymount in a quick turnaround.

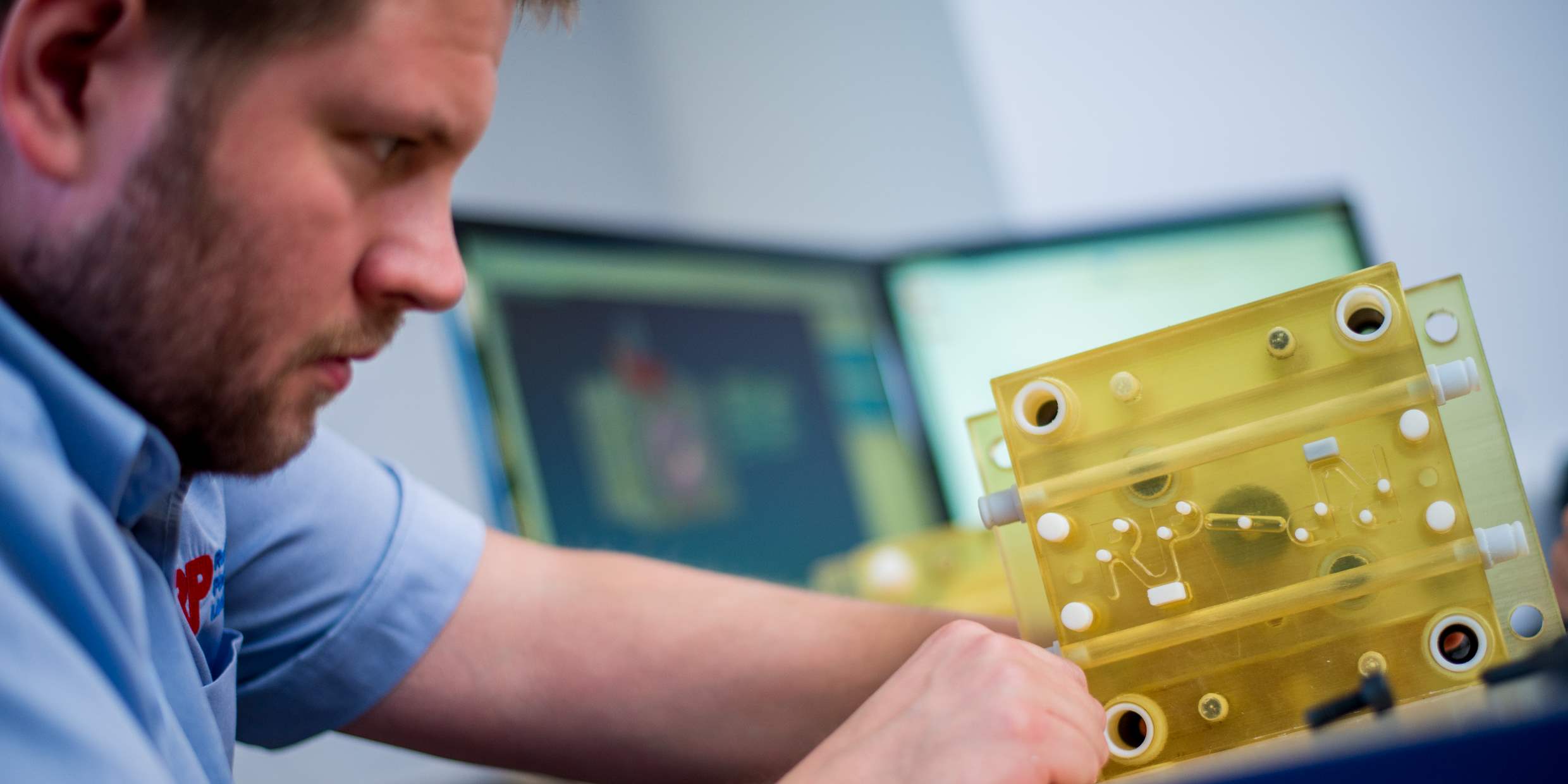

Listening carefully to Joe’s concept, initial designs were produced. Understandably, these went through a number of changes as the product was developed and refined. Along the way 3D printed prototypes were produced in-house to test and refine the ideas further. As part of the service, Rutland Plastics designed and sourced suppliers for the ancillary parts, using their experience to ensure that the parts would be fit for purpose.

“It was really easy to work with Rutland Plastics on this project. They understood my requirements and came up with some innovative design suggestions.” Joe said. “It was really useful having the prototypes. We could visualise the final product and test the different aspects, so refining the design before committing to tooling.”

Rutland Plastics designer, Simon Grainger, said: “Using our 3D printer to produce prototypes of the helmet fixing was particularly useful in refining the design. Without this facility we could not be sure how it would work and could have resulted in expensive tool modifications at a later date.” The result is the world’s first low profile helmet cam adaptor for iPhones. The iPhone is enclosed in a shockproof, water resistant case complete with fixings for solid and vented helmets and a quick release mechanism. The helmet fixing is also adjustable for different styles and the case can also be handheld. There is a software app supplied with the case that has settings for top or side mounting, 720P or 1080P, countdown time for start of recording, and an ability to limit the video length. Footage can be easily shared from the app. It is also possible to use a remote control to start and stop recording within a 10m range.

Joe has the final word: ”Compared to my previous experience, using Rutland Plastics made the process so much more straightforward. As injection moulders they ensured all the parts were designed for manufacture from the outset and that all tooling was of the highest quality. We have already started work on our next project!”

RECENT CASE STUDIES

Free design guide

"*" indicates required fields