Gas Assisted Handles

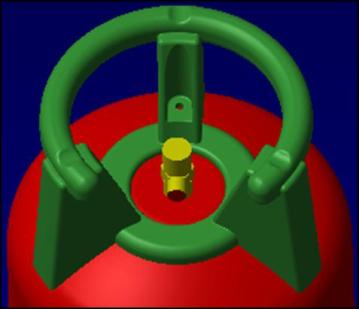

Rutland Plastics was approached by Continental Product Engineering Ltd (CPE) to design and manufacture a handle for a small propane gas bottle. The gas bottles are of a size typically used in the home and leisure market in applications such as patio heaters and outdoor cooking and the handles are traditionally manufactured in metal.

Market research by CPE showed that there are plastic gas bottle handles in the marketplace. These handles tended to be a two piece design and most have a rubber handgrip over-moulded on the underside of the handle to improve the feel. This, however, is an expensive exercise and requires multiple handling of the product.

The plastic handle not only needs to carry a load of specified weight but must withstand the elements and repeated transportation. Therefore, the product needed to be lightweight and robust as well as being easy to assemble and replace if required. The primary feature of this handle is the grip. The section was up to 35mm in some places so it was an obvious candidate for Gas Assisted Injection Moulding. This would hollow out the thick section and reduce the cycle time. The hollowed out centre would also increase the strength of the handle.

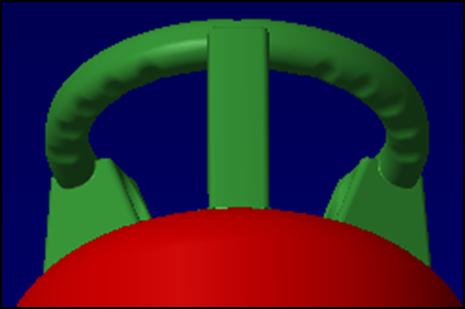

The resulting handle offered significant weight reduction as well as a one piece robust design. The top view shows the thumb grips in the three zones over the main stanchions, which themselves are linked by an integral mounting ring. Compression limiters were used so that the weld lines from the through holes for direct bolting would not be under load, thus avoiding potential failure.

This design utilises both texture and form to create the handgrip on the underside of the handle. This is the area where, on the competitors’ versions they have placed the rubber handgrip. This saves the cost of specialised tooling, double handling and further materials. This may also extend the service life of each handle considerably as over-moulds in thermoplastic rubber are prone to peeling off with constant use.

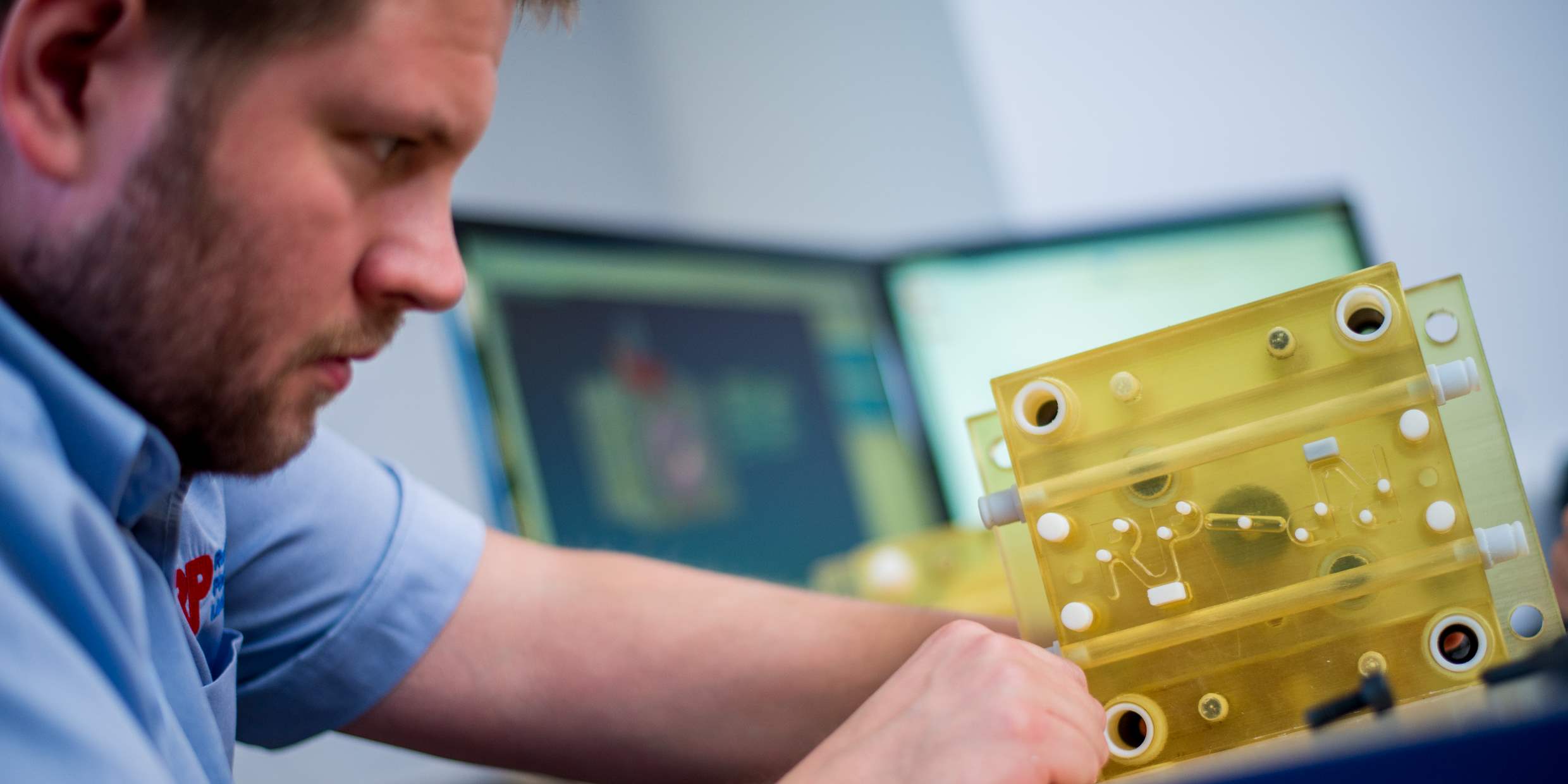

A further constraint in this instance was that when Rutland Plastics was initially approached the gas bottles were already in production overseas and would be available in 10 weeks. Normally, a mould tool of this type would take 10-12 weeks to manufacture and then there would need to be development time on top of that. With weekend working the tool was available in just 7 weeks and all deadlines were met.

RECENT CASE STUDIES

Free design guide

"*" indicates required fields