FLEXIBILITY

It may be that the part you are designing needs to flex in some way. The frequency of the flex and the degree are the first factors that need to be established. You also need to consider the overall function of the part and how flexible or rigid it needs to be in use.

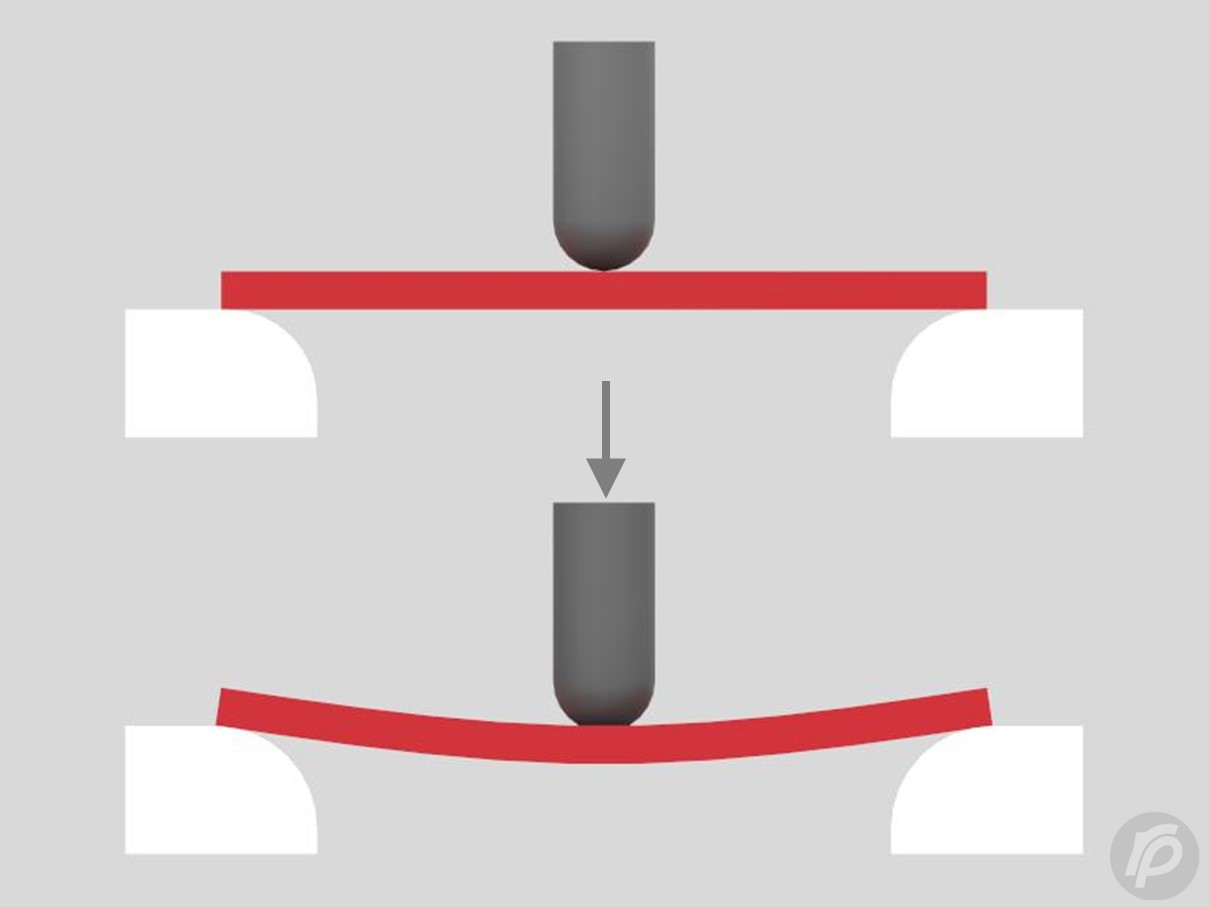

Plastics have a memory and if stressed below their elastic limit for a short period of time they will return to their original shape. Overstressing or longer periods of stress will lead to permanent deformation or creep. Cyclical stress, such as in a hinge, will eventually lead to fatigue and failure.

To allow flex from a design perspective it is possible to have a thinner section where the part needs to flex, such as in the case of a living hinge, for example. For occasional flex choosing a more flexible material with the addition of ribs where stiffness required and absence of ribs in the area of flex is an option.

MATERIAL CHOICE

Material selection will depend on the function of the part. Polypropylene and polyethylene have some flexibility, with low and linear low density polyethylenes tending to be the most flexible of this polymer group. If even more flexibility is required then PP-EPDM or a TPR may be more suitable.

In terms of what to look for on a materials datasheet it is the Flex Modulus or Flex Strength of a material – the lower the number the more flexible it is, i.e. less force is required to deform the material. For TPR’s Shore Hardness can also be used as a guide, with the D scale for harder materials and the A for softer – the higher the number the harder, or stiffer, the material.

FURTHER READING OR LINKS TO ALL GUIDES?

- Design Guide

- Design Development

- Design For Appearance

- Design For Assembly 1

- Design For Assembly 2

- Design For Assembly 3

- Design For Cost Consideration

- Design For Economy

- Design For Mouldability 1

- Design For Mouldability 2

- Design For Mouldability 3

- Design For Precision

- Design For Recyclability

- Design For Stiffness

- Design For Strength

- Design For Time

- Design Summary

- Flame Retardancy

- Flexibility

Free design guide

"*" indicates required fields