IMPACT STRENGTH

It may be that the part you are designing needs to withstand impact. This could be anything from a domestic appliance to a traffic bollard. Car bumpers, for example, are usually plastic and are designed to withstand low speed impacts, typically less than 5mph, such as might be suffered when parking.

In terms of design, ribs may be used and the geometric shape and thickness of the part can also help. Ribs will give the part stiffness which could mean that impact in a certain area may lead to cracking, whereas lack of ribs could result in a part with insufficient rigidity. As with all plastic design there is often a trade-off between design and the properties required.

When selecting a material, the anticipated temperature range also needs to be borne in mind. Certain fillers can considerably increase the impact strength of a material.

MATERIAL FACTORS

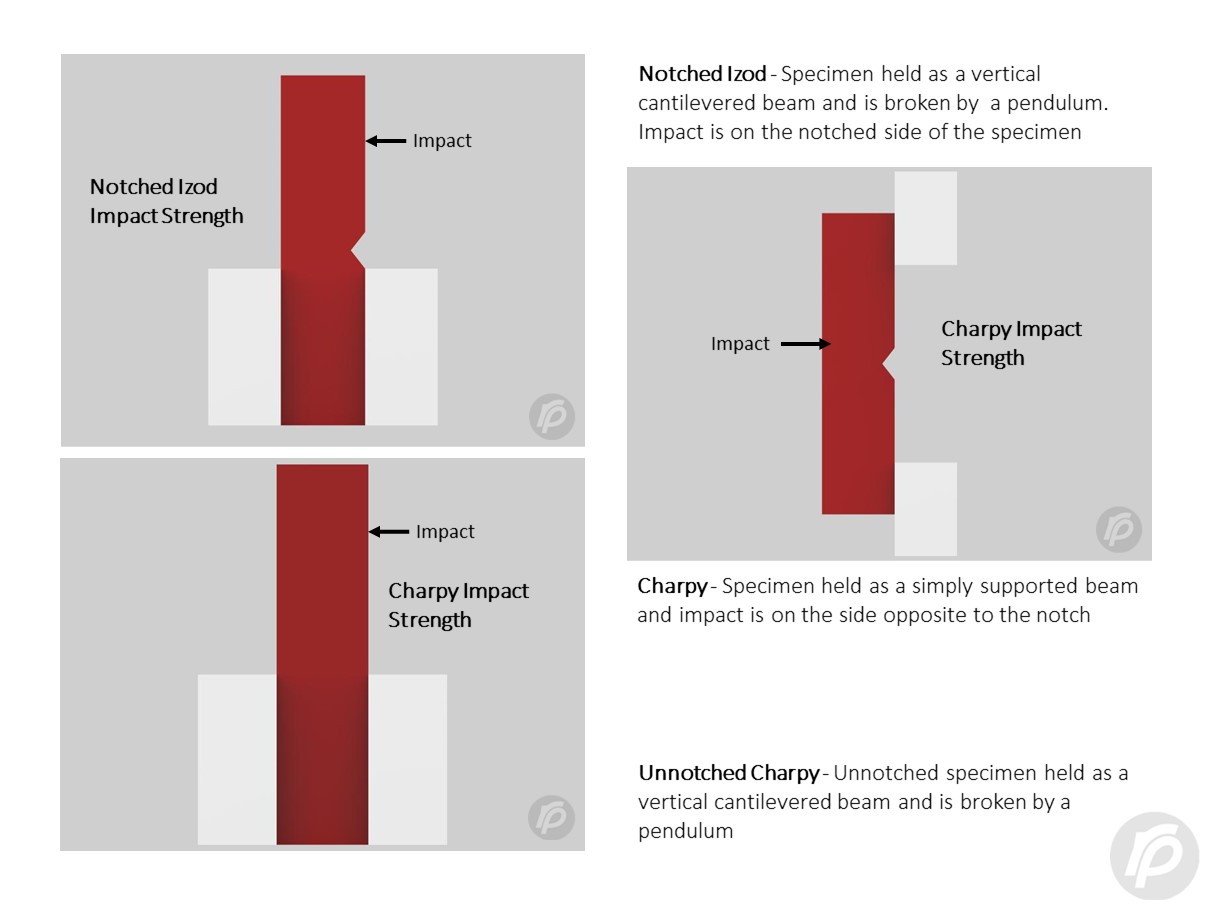

So, what to look for on a datasheet? Well, this one is quite obvious. It is either Izod or Charpy impact strength. These are the two different test methods for measuring the impact strength of a material. Unfortunately, they are not directly comparable with each other but, as with other tests, the higher the number the better the polymer is able to withstand impact without breaking. Other than that, the figures do not enable you to make any calculations but just to be able to rank materials. There are two figures under each standard – notched and unnotched. Many polymers do not break so a stress concentrator is added – notched – therefore, these figures are a better guide.

For better impact strength it is often advisable to go for more flexible polymers, such as polyproylene and polyethylene. However, the particular application needs to be considered before making a final choice. Headlamp lenses, for example, could not be moulded in either of these materials due to the material’s limited transparency. But styrene, for instance, would crack too easily if hit by a stone or something similar. There are tough, more rigid materials and polycarbonate would be used in this instance.

OVERALL CONSIDERATIONS

The overriding concern in design and material selection is that the material should be either extremely tough so that considerable force is needed to deform it, or have a degree of flexibility so that it deforms easily and absorbs the impact. In the case of the former, once the impact goes beyond a certain point the material would probably crack whereas in the case of the latter it may not return to its former shape.

FURTHER READING OR LINKS TO ALL GUIDES?

- Design Guide

- Design Development

- Design For Appearance

- Design For Assembly 1

- Design For Assembly 2

- Design For Assembly 3

- Design For Cost Consideration

- Design For Economy

- Design For Mouldability 1

- Design For Mouldability 2

- Design For Mouldability 3

- Design For Precision

- Design For Recyclability

- Design For Stiffness

- Design For Strength

- Design For Time

- Design Summary

- Flame Retardancy

- Flexibility

Free design guide

"*" indicates required fields