REDEVELOPMENT FOR THE FUTURE

11.01.24

The Southern Manufacturing & Electronics show will be returning to the Farnborough International Exhibition...

28.11.16

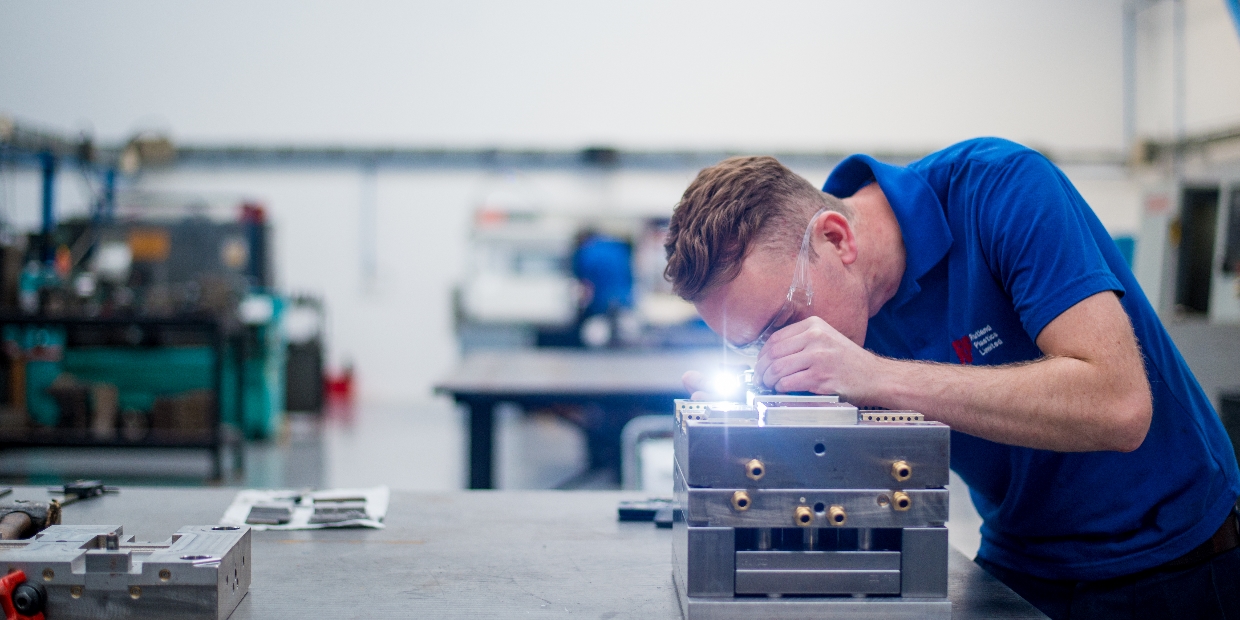

Rutland Plastics has just completed the biggest single investment in its 60 year history....