FLEXURAL STRENGTH AND MODULUS

Flexural strength is the measure of the stiffness of a material, that is to say how well it resists bending.

Testing Strength and Modulus

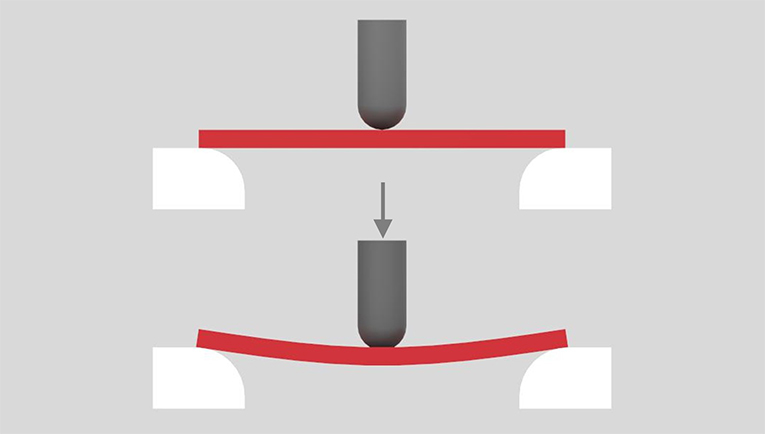

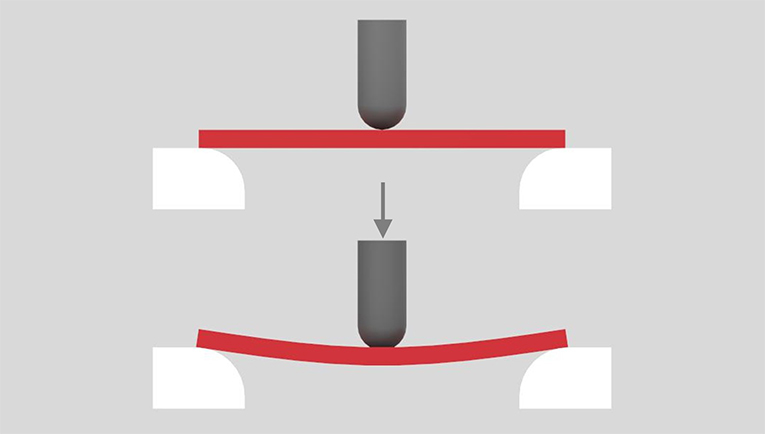

A simple beam of material is supported either end and a load applied at the mid-point. The load is pushed onto the specimen at a constant rate of 2mm per minute.

Measurements are taken using at least five values of load and deflection. From these results a deflection curve is plotted from which the flexural modulus is calculated. As with tensile modulus this is a ratio of stress to strain. Values are reported in MPa (psi).

The only difference between ASTM D790 and ISO 178 is the size of the test bar – 125mm x 12.5mm x 3mm and 80mm x 10mm x 4mm respectively. Therefore, the values reported in ASTM and ISO seldom differ significantly.

Typical results for a selection of materials as follows:

| Material | Flex Strength | Flex Modulus |

|---|---|---|

| ABS | 70 | 2.5 |

| Acetal | 85 | 2.5 |

| 30% Glass Filled Acetal | 150 | 7.5 |

| Polypropylene | 40 | 1.5 |

There are various measures which are defined as follows:

| Term | Definition |

|---|---|

| Flexural Modulus | The ratio of stress to strain |

| Flexural Stress at Yield | The stress corresponding to test specimen yield |

| Flexural Stress at Break | The stress corresponding to test specimen failure |

| Flexural Strength | The maximum stress sustained by a specimen during testing |