POLYMETHYL METHACRYLATE (ACRYLIC)

Acrylic is a hard, rigid material (it has a hardness comparable to aluminium) which maintains its clarity even with thick sections and after long exposures to outside atmospheres. However, it is easily scratched by dust or cleaning.

Please Note: This page is for information purposes only. Rutland Plastics is an Injection Moulder and does not supply polymers.

PROPERTIES

PMMA has high strength but is brittle. It is resistant to ultra violet radiation and weathering although can be vulnerable to crazing which can be worsened by detergents, greases and oils. It is flammable. Acrylic tends to attract dust so ideally an antistatic additive should be used.

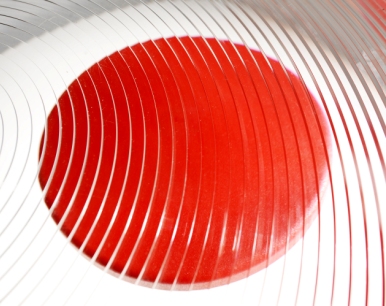

COLOURING

As the material is clear a wide range of colours is possible, both solid and translucent.

Finishing

Mouldings can be joined using solvents or welded using ultrasonic welding, hot plate and friction. Parts can be machined but care needs to be taken to avoid scratching.

CHEMICAL RESISTANCE

| Mineral Acids (dilute) | Excellent |

| Mineral Acids (concentrated) | Poor |

| Alkali | Excellent |

| Alcohol | Good |

| Ketone | Poor |

| Aromatic Hydrocarbon | Poor |

| Chlorinated Hydrocarbon | Poor |

| Detergents | Excellent |

| Oils, Greases | Excellent |

APPLICATIONS

Because of its good UV stability and excellent clarity many applications of acrylic are lenses, lighting covers (indoor and outdoor), dials and control panels. Often used for lenses on rear lights of cars.