Stuart Johnston talks to BBC Radio Leicester.

2021 was quite a busy year for us at Rutland Plastics; celebrating our 65th Birthday and being named Processor of the Year by the Plastics Industry Awards. BBC Radio Leicester invited us to have a chat with Summaya Mughal about recent events at Rutland Plastics. Our Director, Stuart Johnston spoke to Summaya about the last two years; surviving the pandemic, making visors and winning the Processor of the year in 2021.

Summaya - Tell me about how the pandemic impacted your business?

Stuart - The first lockdown was a bit of a nightmare as some orders just stopped overnight but we were approached by Oakham School to help make visors for local hospitals and frontline healthcare workers. We offered to make an injection mould tool for free which increased their capacity from a couple of hundred a week to tens of thousand a week and these visors were distributed around Leicestershire and Rutland for free. We were passionate about the fact that if people are working in a dangerous environment they should have the appropriate PPE. We decided that we were not going to make a profit from this but that we were going to do this free of charge as it was the right thing to do, and was also a very fulfilling thing to do.

Summary - How about now, are you still making visors and valves for compressed oxygen?

Stuart - No, the visors are all now supplied and sourced by the NHS but we are still making compressed oxygen valves as that’s a regular product that we make and that you would see if you went into hospital.

Summaya - So what do you do at Rutland Plastics?

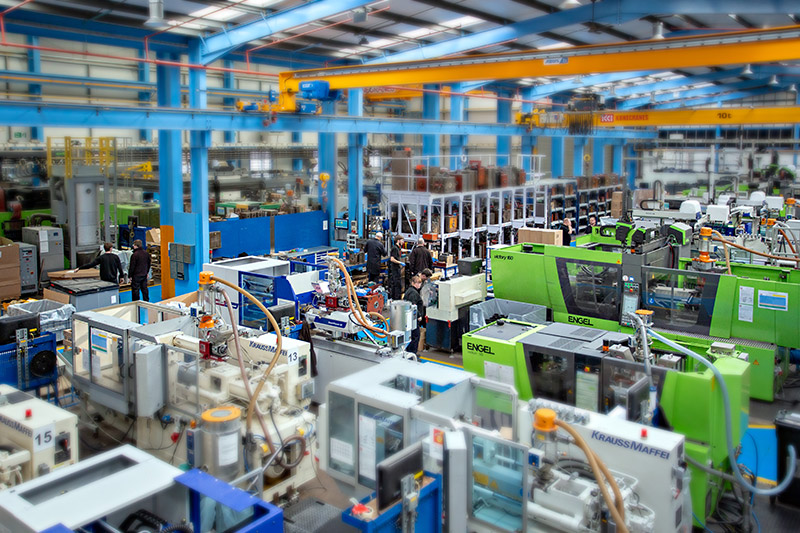

Stuart - We are a plastic injection moulder which means that we make plastic products on behalf of other companies. It’s a wide range of products we make, healthcare products, products that bring water and gas to your house, camping equipment, invalid aids, reusable coffee cups, electronics casings - a real variety of things.

Summaya - There's been a massive move against plastics but I know that you’re really careful about your carbon footprint. What are the steps you’re taking as a company?

Stuart - As a business, we see this as incredibly important, we have invested heavily in solar electricity, we have about 1000 solar panels on our roof which provides about 15% of our electricity, and we are looking to double that in the next 12 months. As well as that we are really conscious that we reduce pellet loss and minimise plastic waste in the environment.

Summaya - What are the ways you can do that? What are your thoughts about plastics and waste, you’re kind of at the heart of that aren't you?

Stuart - Well, plastic is a resource like any other in the world and we need to protect it and use it wisely. The main thing to remember is that there is nothing out there that can do what plastics can do. If we look at the recent pandemic, plastics have been at the core of solving problems, whether it be through patients who require ventilation or PPE; all these things are made from plastics and it's an incredibly important resource in the world.

Summaya - I agree, but there can be really damaging effects so what do we do?

Stuart - Well, first of all, it starts with design, so we help our customers design their products so that they use as little plastic as possible so they are really efficient. Also, we need to be conscious of waste, not just waste in the manufacturing process but also waste throughout the life of the product and what happens when the product comes to the end of its life and how that can be reused or recycled.

Summaya - Are there ways that that breakdown of plastic process can be improved?

Stuart - That’s going to come in the future so that the plastic is broken down into a compostable form so that it won't have a damaging effect on the environment.

Summaya - Congratulations on the Processor of the Year award, tell me a bit about this.

Stuart - So the Plastic Industry award is the UK's premier industry award. We were nominated for Processor of the Year, went through the interview process and we won! It was a great achievement, particularly in our 65th year and as we've just experienced the most difficult 24 months of the companies history. I must say thank you to all our employees as it was them who did all the work.

Summaya - So what do the next 65years have in store?

Stuart - Well, steady and organic growth and definitely based here in Rutland, to make sure that we are at the heart of the community and the plastics community. Steve, who’s Managing Director is the 3rd generation of his family at the company but there are also third and fourth generations of other families in the business and we want that to continue.

It was great to get the opportunity to talk to the local community about what we do at Rutland Plastics and to promote British Manufacturing and the Plastics Industry.

RECENT POSTS

Free design guide

"*" indicates required fields